Can ceramic electrophoretic coating casement windows become the benchmark for high-performance building windows?

Release Time : 2025-11-13

In today's world, where green building and high-quality living environments are increasingly valued, windows and doors, as the weakest link in the building envelope in terms of thermal performance, directly determine residential comfort and energy efficiency through their thermal insulation, sound insulation, airtightness, and durability. Ceramic electrophoretic coating casement windows, with their innovative material processes, precise structural design, and systematic sealing technology, are redefining the standards for high-end energy-efficient windows and doors. They not only possess a smooth, porcelain-like surface texture but also integrate multiple technologies to silently construct a highly efficient barrier against heat, cold, wind, rain, and noise.

The core advantage of ceramic electrophoretic coating casement windows lies first in their unique ceramic electrophoretic inner surface treatment process. The inner side of the window frame uses ceramic enamel coating electrophoresis technology to form a dense, uniform, and high-hardness protective layer with a delicate touch like glazed ceramic, possessing stain resistance, wear resistance, and easy cleaning properties. Compared to traditional powder coating or anodizing, electrophoretic coating offers stronger adhesion and superior weather resistance, remaining colorfast and peel-free over long-term use, adding a subtle yet sophisticated aesthetic to interior spaces.

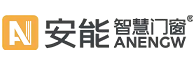

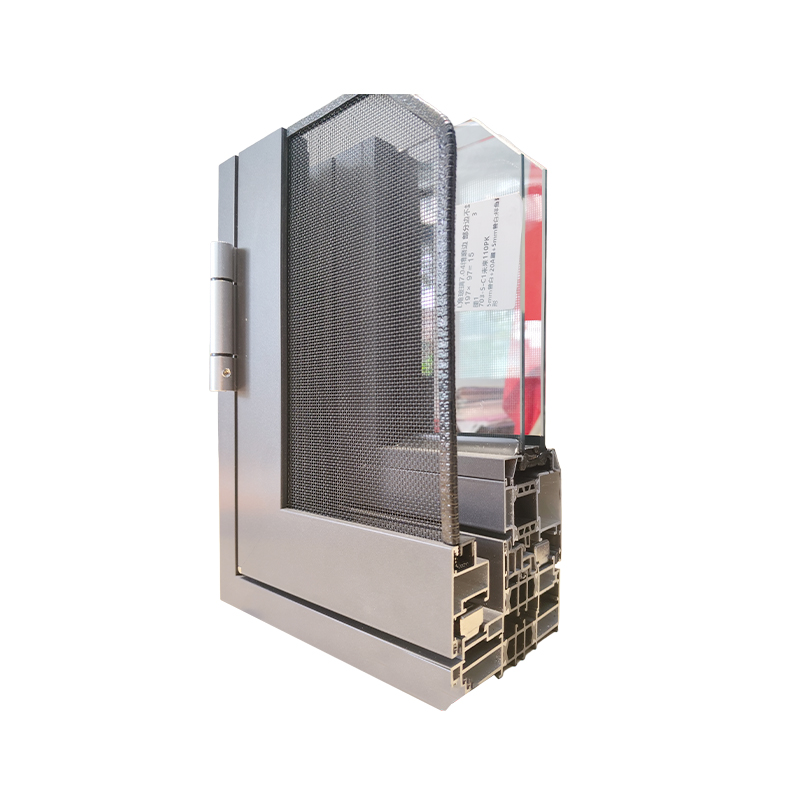

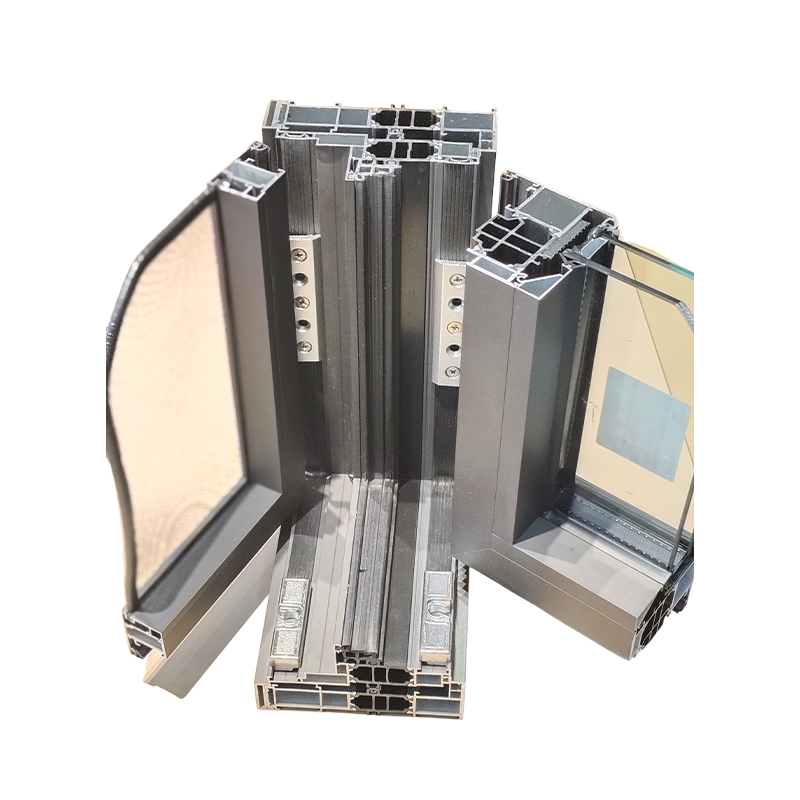

Regarding structural stability, the product employs a two-component screw-hole injection process combined with high-performance adhesives for reinforcement. High-strength two-component polyurethane structural adhesive is injected into the corners and cross-sections of the outer frame, glass window frame, and screen window frame, achieving a dual connection method of "seamless bonding + mechanical locking." This process completely replaces traditional corner bracket splicing, significantly improving the overall rigidity and deformation resistance of the window frame, effectively resisting strong wind pressure and structural fatigue from long-term use, ensuring smooth opening and closing without deformation for many years.

The sealing and drainage system also reflects meticulous craftsmanship. The bottom of the window sash is equipped with an automatic opening and closing drain design, allowing rainwater to drain quickly after entering the cavity and automatically closing after rain stops, preventing backflow and seepage, balancing efficient drainage and airtightness. The entire window utilizes an integrated, vulcanized, welded isothermal sealing strip. This strip is pre-vulcanized in the factory, resulting in a seamless, uninterrupted fit that perfectly integrates with the frame, significantly improving water tightness and air tightness. Both fixed and sliding windows come standard with double-layered sealing strips (interior and exterior), eliminating the need for on-site caulking and preventing seal failure due to construction errors.

The thermal insulation performance reaches industry-leading levels. By inserting high-performance thermal insulation strips into the finished frame, multiple independent closed cavities are formed, effectively blocking the heat conduction path of the metal frame. The insulation strips are arranged to form continuous vertical isotherms, significantly reducing the overall window heat transfer coefficient (U-value). This reduces indoor heat loss in winter and blocks external heat radiation in summer, significantly reducing air conditioning and heating energy consumption and meeting energy-saving design standards in extremely cold and hot-summer-cold-winter regions.

Furthermore, a sealed adhesive strip, standard across the entire series, not only strengthens the structural bond between the glass and the window frame but also significantly improves wind pressure resistance, ensuring the window remains stable and safe even during typhoons or strong winds at high altitudes. The dual-sealing system, both indoor and outdoor, combined with a multi-cavity structure, achieves superior sound insulation, effectively blocking external disturbances such as traffic noise and construction noise, creating a quiet indoor environment.

At a deeper level, this ceramic electrophoretic coating casement window represents a technological leap in window and door manufacturing from "component assembly" to "system integration." All key processes—electrophoretic coating, structural sealant injection, rubber strip vulcanization, and thermal insulation strip installation—are completed in a highly automated factory environment, ensuring product consistency and reliability. Users receive not just a window, but a proven, high-performance building envelope solution.

In summary, the ceramic electrophoretic coating casement window transcends the traditional window and door category, becoming a high-end system window paradigm that integrates aesthetics, energy efficiency, safety, and durability. With its ceramic-like surface, it presents a warm and smooth texture; with its isothermal cavity, it blocks heat transfer; and with its integrated seal, it protects a tranquil space. When a window stands firm in the wind and rain, and remains cool under the scorching sun, it is the silent protection of this sophisticated system behind it—this seemingly sturdy ceramic electrophoretic coating casement window is actually an indispensable energy-saving barrier and a symbol of quality in modern green buildings.

The core advantage of ceramic electrophoretic coating casement windows lies first in their unique ceramic electrophoretic inner surface treatment process. The inner side of the window frame uses ceramic enamel coating electrophoresis technology to form a dense, uniform, and high-hardness protective layer with a delicate touch like glazed ceramic, possessing stain resistance, wear resistance, and easy cleaning properties. Compared to traditional powder coating or anodizing, electrophoretic coating offers stronger adhesion and superior weather resistance, remaining colorfast and peel-free over long-term use, adding a subtle yet sophisticated aesthetic to interior spaces.

Regarding structural stability, the product employs a two-component screw-hole injection process combined with high-performance adhesives for reinforcement. High-strength two-component polyurethane structural adhesive is injected into the corners and cross-sections of the outer frame, glass window frame, and screen window frame, achieving a dual connection method of "seamless bonding + mechanical locking." This process completely replaces traditional corner bracket splicing, significantly improving the overall rigidity and deformation resistance of the window frame, effectively resisting strong wind pressure and structural fatigue from long-term use, ensuring smooth opening and closing without deformation for many years.

The sealing and drainage system also reflects meticulous craftsmanship. The bottom of the window sash is equipped with an automatic opening and closing drain design, allowing rainwater to drain quickly after entering the cavity and automatically closing after rain stops, preventing backflow and seepage, balancing efficient drainage and airtightness. The entire window utilizes an integrated, vulcanized, welded isothermal sealing strip. This strip is pre-vulcanized in the factory, resulting in a seamless, uninterrupted fit that perfectly integrates with the frame, significantly improving water tightness and air tightness. Both fixed and sliding windows come standard with double-layered sealing strips (interior and exterior), eliminating the need for on-site caulking and preventing seal failure due to construction errors.

The thermal insulation performance reaches industry-leading levels. By inserting high-performance thermal insulation strips into the finished frame, multiple independent closed cavities are formed, effectively blocking the heat conduction path of the metal frame. The insulation strips are arranged to form continuous vertical isotherms, significantly reducing the overall window heat transfer coefficient (U-value). This reduces indoor heat loss in winter and blocks external heat radiation in summer, significantly reducing air conditioning and heating energy consumption and meeting energy-saving design standards in extremely cold and hot-summer-cold-winter regions.

Furthermore, a sealed adhesive strip, standard across the entire series, not only strengthens the structural bond between the glass and the window frame but also significantly improves wind pressure resistance, ensuring the window remains stable and safe even during typhoons or strong winds at high altitudes. The dual-sealing system, both indoor and outdoor, combined with a multi-cavity structure, achieves superior sound insulation, effectively blocking external disturbances such as traffic noise and construction noise, creating a quiet indoor environment.

At a deeper level, this ceramic electrophoretic coating casement window represents a technological leap in window and door manufacturing from "component assembly" to "system integration." All key processes—electrophoretic coating, structural sealant injection, rubber strip vulcanization, and thermal insulation strip installation—are completed in a highly automated factory environment, ensuring product consistency and reliability. Users receive not just a window, but a proven, high-performance building envelope solution.

In summary, the ceramic electrophoretic coating casement window transcends the traditional window and door category, becoming a high-end system window paradigm that integrates aesthetics, energy efficiency, safety, and durability. With its ceramic-like surface, it presents a warm and smooth texture; with its isothermal cavity, it blocks heat transfer; and with its integrated seal, it protects a tranquil space. When a window stands firm in the wind and rain, and remains cool under the scorching sun, it is the silent protection of this sophisticated system behind it—this seemingly sturdy ceramic electrophoretic coating casement window is actually an indispensable energy-saving barrier and a symbol of quality in modern green buildings.