What factors affect the color durability of ceramic electrophoretic coating casement windows?

Release Time : 2026-01-09

The colorfastness of ceramic electrophoretic coating casement windows is one of their core performance indicators, directly affecting their aesthetics and lifespan. Its color stability is influenced by multiple factors, encompassing coating material characteristics, application techniques, environmental conditions, and daily maintenance, requiring a systematic analysis from technical, environmental, and usage perspectives.

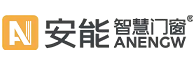

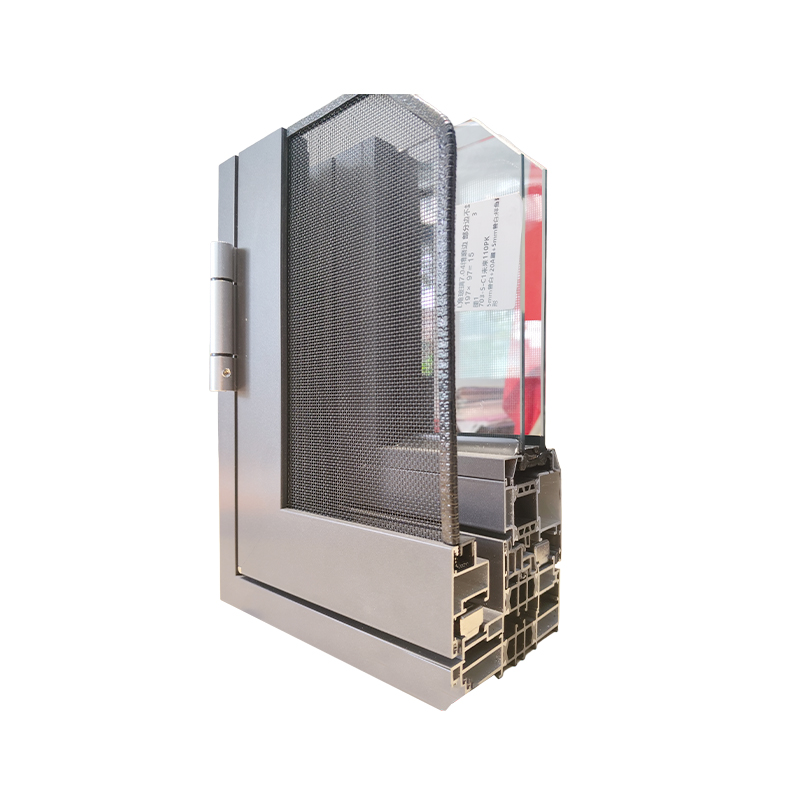

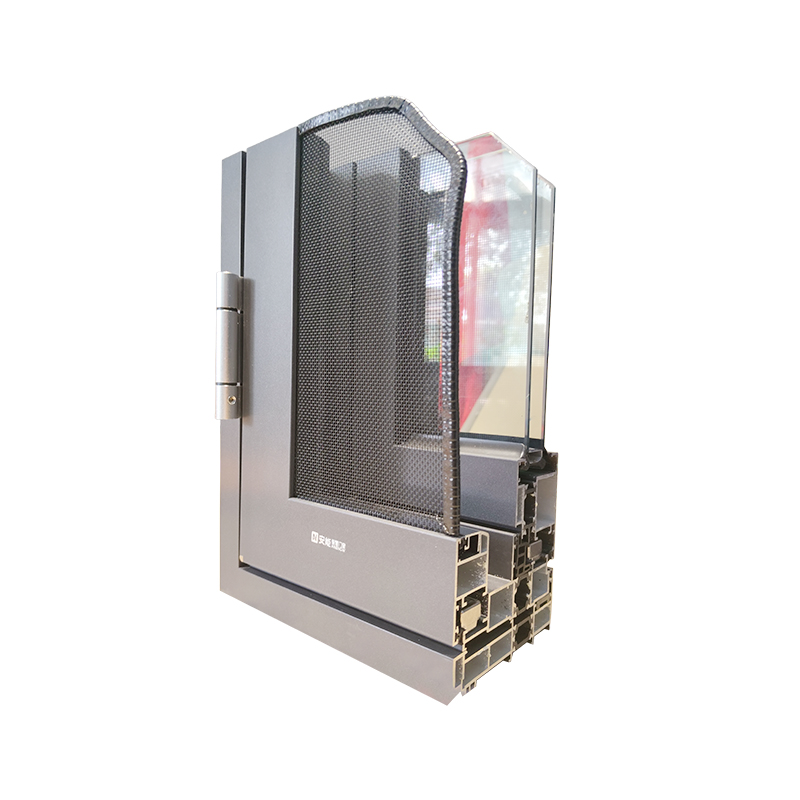

The choice of coating material is fundamental to colorfastness. Ceramic electrophoretic coatings use nano-sized ceramic particles as their core component, forming a dense protective layer on the aluminum alloy surface through electrolysis. Their chemical stability is superior to traditional coatings, resisting the erosion of ultraviolet rays, acid rain, and salt spray, thus slowing down color fading. However, different brands of ceramic coatings have different formulations, and some products can further extend the color retention period by adding special stabilizers or ultraviolet absorbers. For example, ceramic coatings containing silica have higher hardness and stronger wear resistance, reducing the risk of localized fading due to surface scratches.

The standardization of the application process directly affects the bonding strength between the coating and the substrate. Ceramic electrophoretic coating requires multiple processes, including pretreatment, electrophoretic deposition, and curing. Neglecting any step can lead to uneven color or decreased adhesion. For example, if the aluminum alloy substrate is not thoroughly degreased or phosphated, the coating is prone to peeling. Improper voltage and temperature control during electrophoresis can result in uneven coating thickness and inconsistent color depth. Insufficient temperature and time during curing can lead to incomplete hardening, resulting in chalking or discoloration after long-term use. Professional construction teams can ensure uniform coating coverage and improve color stability by precisely controlling process parameters.

Environmental factors pose an external challenge to color durability. Ultraviolet radiation is one of the main causes of coating aging; prolonged exposure to strong light can cause molecular chain breakage, leading to gradual color fading. High humidity environments can accelerate moisture penetration into the coating, causing internal corrosion or mold growth, affecting color purity. Furthermore, salt in the air in coastal areas and acid and alkali pollutants in industrial areas can corrode the coating surface, damaging its gloss and color. Therefore, the weather resistance of ceramic electrophoretic coating casement windows under harsh climatic conditions requires both material optimization and process improvement.

Daily maintenance habits have a long-term impact on color durability. Using abrasive brushes or strong corrosive cleaners during cleaning may scratch the coating surface, reducing its protective performance; long-term neglect leading to dirt accumulation may cause microbial growth, further damaging the coating structure. It is recommended to wipe regularly with a neutral detergent and a soft cloth, avoiding impacts from hard objects to extend the color retention period. In addition, avoiding prolonged direct sunlight on doors and windows when parking, or installing sunshades, can also reduce UV damage to the coating.

Coating thickness and uniformity are the physical guarantees of color durability. The thickness of ceramic electrophoretic coatings usually needs to be controlled within a specific range; too thin and the protective performance will be insufficient, too thick and it may cause cracking or peeling. During construction, the coating thickness must be precisely controlled using equipment to ensure even coverage of all parts of the ceramic electrophoretic coating casement window, avoiding uneven color depth due to localized thickness differences. For example, corners or complex shapes require enhanced coating to eliminate blind spots in the process.

Color selection itself also affects durability. Darker coatings (such as black and dark gray) absorb more ultraviolet light, and their risk of fading after long-term use may be slightly higher than that of lighter colors. Metallic or pearlescent coatings, due to the presence of special pigments, require additional processing to ensure their weather resistance. Therefore, the color design stage must comprehensively consider the usage environment and material characteristics to select a solution that combines aesthetics and durability.

The color durability of ceramic electrophoretic coating casement windows is the result of the combined effects of materials, processes, environment, and maintenance. By selecting high-quality coatings, standardizing construction procedures, optimizing environmentally adaptable design, and implementing scientific maintenance, color stability can be significantly improved to meet long-term usage requirements. In the future, with the further development of nanotechnology and environmentally friendly coatings, the color durability of ceramic electrophoretic coatings will be further improved, providing a more reliable solution for the high-end door and window market.