How does the hinge mechanism of tilt-and-turn windows achieve flexible multi-angle opening and closing?

Release Time : 2025-12-30

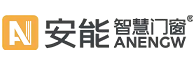

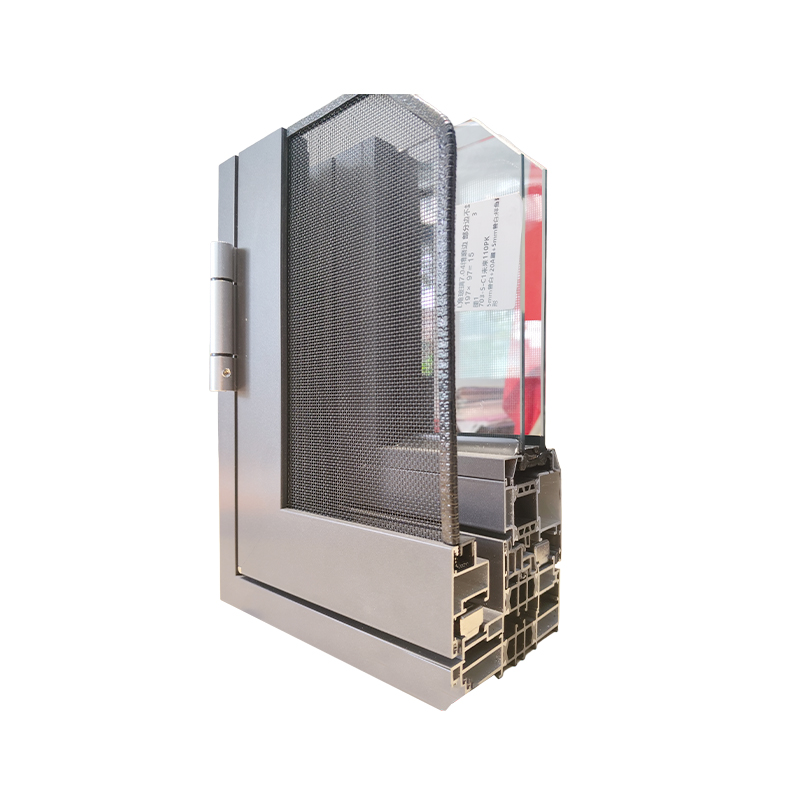

The hinge mechanism of tilt-and-turn windows integrates rotation and tilting functions into a single structure through precise mechanical design, enabling flexible opening and closing at multiple angles. Its core lies in the synergistic effect of a dual-axis linkage structure and a damping system, satisfying space utilization needs while ensuring operational stability and safety.

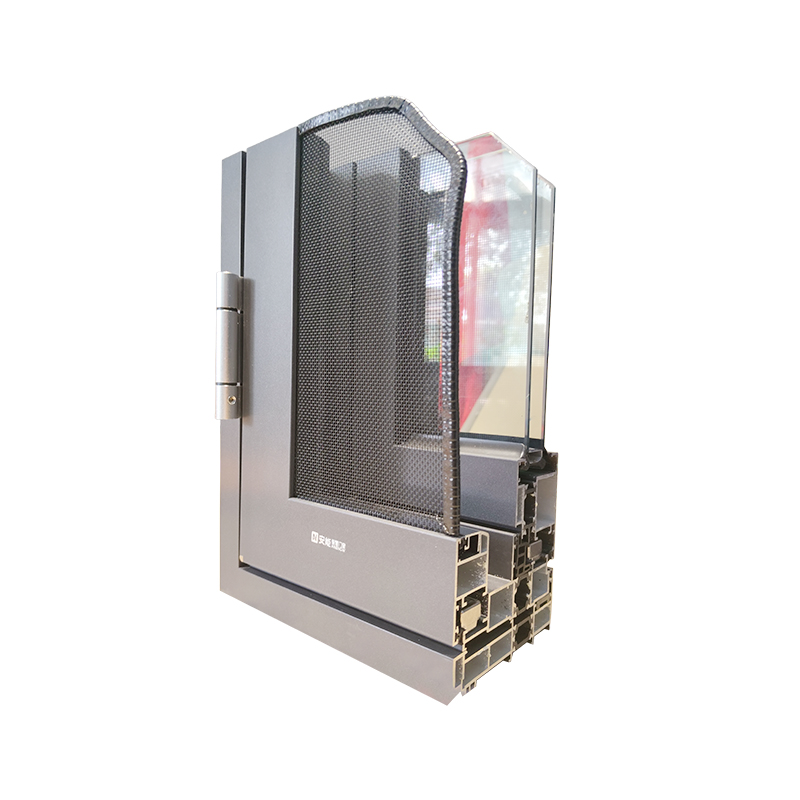

The dual-axis design of the hinge is the foundation for the multi-angle adjustment of tilt-and-turn windows. Traditional single-axis hinges can only achieve rotation in one direction, while the tilt-and-turn window hinge, through its dual-axis linkage structure, allows the window sash to move simultaneously around both the horizontal and vertical axes. The horizontal axis handles the window sash's rotation, allowing it to rotate 360 degrees within a plane to adapt to different ventilation or lighting needs. The vertical axis controls the window sash's tilt angle, allowing it to tilt downwards or upwards within a certain range during rotation. For example, a kitchen cabinet window sash can rotate 90 degrees and then tilt downwards by 10 degrees, making it easier for users to reach items without having to tiptoe. The coordinated operation of the dual axes is achieved through gear sets or linkage arms, ensuring that rotation and tilting movements do not interfere with each other and that stable stopping is possible at any angle.

The introduction of a damping system is key to the smooth closing of tilt-and-turn windows. Traditional hinges are prone to impact due to inertia when closing, causing the window sash to collide with the frame. Tilt-and-turn windows, however, incorporate hydraulic or pneumatic dampers in their hinges. Through the slow movement of a piston within an oil or air chamber, the closing speed is reduced from an initial rapid motion to a stable state. For example, when the window sash closes, the damper generates resistance through the flow of hydraulic oil or gas, automatically slowing the sash as it approaches the closed position, preventing noise or damage from impact. The damping force can be adjusted according to the weight of the window sash; light-duty sashes use a low-damping design, while heavy-duty sashes use a high-damping design, ensuring smooth closing for window sashes of different sizes.

The ability to stop at any angle is the core mechanism for tilt-and-turn windows to achieve multi-angle stopping. The hinges utilize either friction plates or a ratchet mechanism for positioning. Friction plate positioning adjusts the pressure between two sets of high-precision friction plates, ensuring the window sash remains stable at any angle due to friction exceeding its own weight. Racket positioning, on the other hand, achieves more precise angle locking through the engagement of a pawl and a ratchet wheel, suitable for scenarios requiring high positioning accuracy. For example, in medical equipment cabinets, tilt-and-turn windows use ratchet positioning to ensure the cabinet door remains stable after opening, facilitating quick access to instruments for medical staff and preventing door wobbling from interfering with operation.

Precise control of the tilt angle is achieved through limit blocks. Adjustable limit blocks are installed inside the hinges to limit the maximum tilt angle of the window sash, preventing deformation or detachment due to excessive tilting. The position of the limit blocks can be adjusted according to actual needs; for example, the tilt angle of a bathroom mirror cabinet window sash is typically set at 8 degrees to avoid glare from the mirror while ensuring structural safety. Meanwhile, the tilting and rotating mechanisms work seamlessly together, eliminating the need for step-by-step adjustments during operation. A single hand can perform the integrated "rotation + tilt" action, significantly improving ease of use.

Material selection and structural optimization are fundamental to the long-term stable operation of tilt-and-turn window hinges. The hinge body is made of stainless steel or high-strength alloy materials, possessing excellent corrosion resistance and durability, adapting to harsh environments such as humidity and high temperatures. For example, 316 stainless steel, due to the addition of molybdenum, has 3-5 times the salt spray corrosion resistance of 304 stainless steel, making it suitable for scenarios such as bathroom mirror cabinets. Structurally, the hinge uses thickened connecting arms and precision casting technology to enhance its resistance to deformation, preventing bending or breakage due to stress after long-term use.

The tilt-and-turn window hinge mechanism achieves flexible opening and closing of the window sash at multiple angles through technologies such as dual-axis linkage, damping buffer, arbitrary stopping and positioning, limit control, and material optimization. Its design not only meets the needs of modern architecture for space utilization and functional diversity but also enhances the user experience through humanized details, making it a core component of high-end door and window systems.