How effective is the ceramic electrophoretic coating casement window in preventing mold in humid environments?

Release Time : 2025-10-30

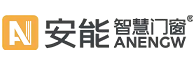

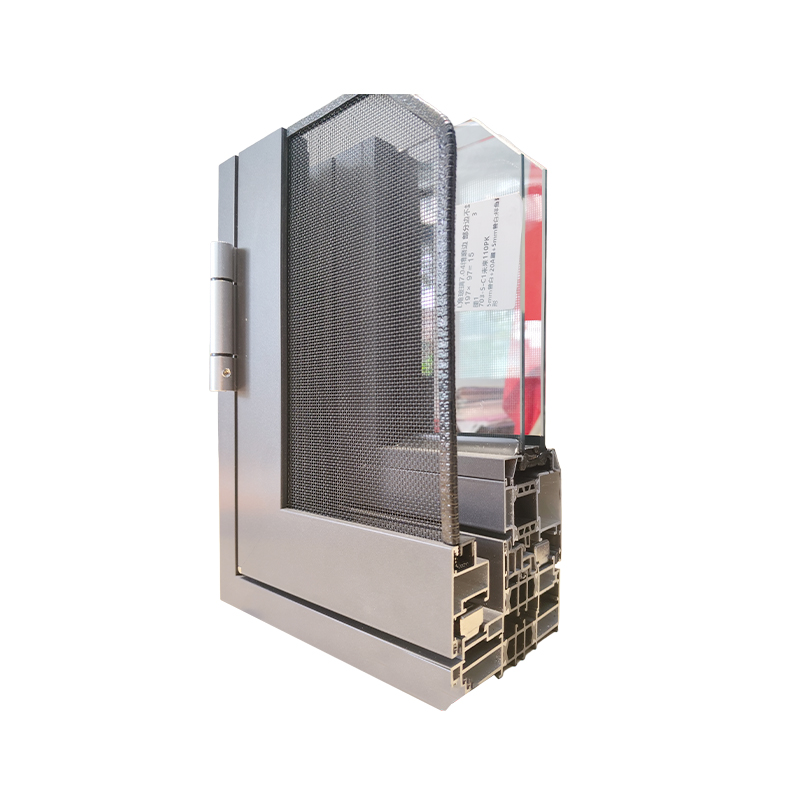

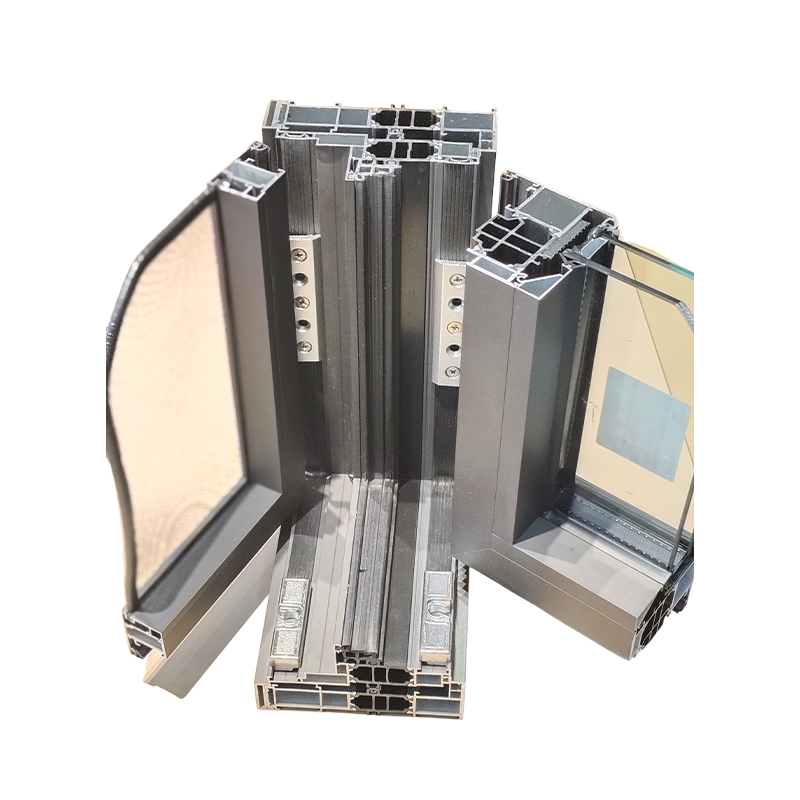

The anti-mold effect of ceramic electrophoretic coating casement windows in humid environments stems from the dual protection of its material properties and process design. The ceramic electrophoretic coating uses inorganic non-metallic materials as its core, employing electrophoretic deposition technology to uniformly adhere ceramic particles such as alumina and zirconium oxide to the aluminum surface, forming a dense and stable protective layer. This structure not only gives the window a delicate, ceramic-like texture but also acts as a physical barrier, preventing direct contact between moisture and mold, thus inhibiting mold growth at its source.

In humid environments, traditional door and window surfaces are prone to blistering and peeling due to moisture penetration, providing a breeding ground for mold. The advantage of ceramic electrophoretic coating lies in its excellent weather resistance and corrosion resistance. The composite formula of alumina and zirconium oxide gives the coating high hardness and wear resistance, maintaining surface integrity even under prolonged exposure to high humidity, preventing localized dampness caused by coating damage. Furthermore, the ceramic particles in the coating achieve moisture permeability through their microporous structure, rather than simply blocking it. This "hydrophobic and breathable" property prevents moisture buildup while maintaining the window's "breathability," further reducing the probability of mold growth.

The durability of the anti-mold effect also relies on the chemical stability of the ceramic electrophoretic coating. Inorganic ceramic materials have natural resistance to corrosive media such as acid and alkali sprays and salt sprays, especially in humid coastal areas, effectively resisting salt erosion from seawater evaporation. Traditional organic coatings are prone to chemical decomposition in humid environments, producing nutrients that become a "culture medium" for mold. The ceramic electrophoretic coating, through its inorganic properties, eliminates this risk, achieving an antibacterial and anti-mold rating that meets the national Class 0 standard, requiring no additional anti-mold treatment for long-term use.

In practical applications, the ceramic electrophoretic coating casement window performs particularly well in high-humidity areas such as bathrooms and basements. Its self-cleaning function reduces stain adhesion; even if dust or water stains accumulate, a simple wipe restores cleanliness, preventing mold growth caused by dirt buildup. Meanwhile, the coating's durable gloss ensures the window retains its aesthetic appeal even after long-term use, preventing discoloration or dulling due to humidity, thus balancing functionality and aesthetics.

Compared to ordinary electrophoretic coatings or powder coatings, ceramic electrophoretic coatings offer significantly better mold resistance. Ordinary coatings are prone to fading, color variations, and even corrosion due to microbial metabolic products in humid environments. Ceramic electrophoretic coatings, however, form stable chemical bonds through a high-temperature curing process, resulting in superior anti-aging properties. Furthermore, its environmentally friendly characteristics meet modern home furnishing needs; the coating production process does not add organic solvents, and there is no formaldehyde or VOC release, preventing the exacerbation of indoor humidity problems due to volatile substances during use.

For consumers, choosing ceramic electrophoretic coating casement windows means optimized long-term costs and maintenance efficiency. Its durability is significantly higher than traditional coatings, reducing the frequency of replacement due to mold, especially in humid climates. At the same time, the coating's easy-to-clean properties reduce daily maintenance difficulties; users do not need to frequently use chemical cleaners, further avoiding secondary dampness problems caused by cleaner residue.

Ceramic electrophoretic coating casement windows offer a systematic solution for mold prevention in humid environments through material innovation and process upgrades. Their inorganic ceramic properties, hydrophobic and breathable structure, chemical stability, and self-cleaning function collectively create a multi-layered mold-resistant system, extending the lifespan of the window and improving the health and comfort of the living environment, making them the preferred choice for windows in humid areas.